The deposition of the chrome is really constant and precise, without any rotation of the bar on its axis.

The tank is small and the chemical solution contained is many times lower than in old technology.

The lower surface of the liquid produces less fumes and it is really simple and economical to contain it in anti-pollution coatings: reducing the fumes reduces the cost of their treatment.

No conceptual limitation on the length of the bars to be chromed.

Easy automation implies a very constant quality and makes production independent of the operators' ability.

The continuous chroming process in passing

it is applied to bars, tubes and other products with axial symmetry, within certain limits it is possible to chrome also pieces with variable cross-section along the axis maintaining the uniformity of the thickness.

The chrome-plated pass-through system ensures the chrome-plating of pieces without any length limit.

The chrome-plated technology in continuous passage

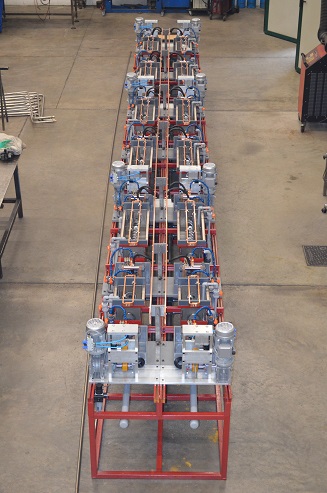

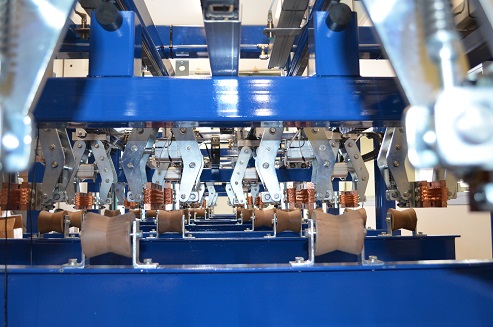

it also allows to have chromium plating machines with more lines, giving the possibility to chromate at the same time different diameters, assuring productive flexibility and economic advantages.

CONTINUOUS CHROMING Ø 6 - 12 mm

CONTINUOUS CHROMING Ø 60 - 130 mm

CONTINUOUS CHROMING Ø 30 - 80 mm

CONTINUOUS CHROMING Ø 30 - 90 mm

CONTINUOUS CHROMING Ø 20 - 50 mm

We listen to every customer's need and create an ad hoc system with him. There is not an Ilmar plant identical to another, being able to manage the length of the tanks, working diameters and length of the loading and unloading benches in a total manner.

Over the years, the name ILMAR has become among the best known in the environment of electrolytic, galvanizing and purification plants. Only ILMAR produces continuous chrome-plating machines of this kind, with unmatched quality, timing and management costs.

Repeatability and rapid assistance in every part of the world: ready to receive any kind of request for assistance, replacement or upgrade of our systems. Interventions scheduled in the day or at most the next day in Italy and in a few days in every other part of the world.

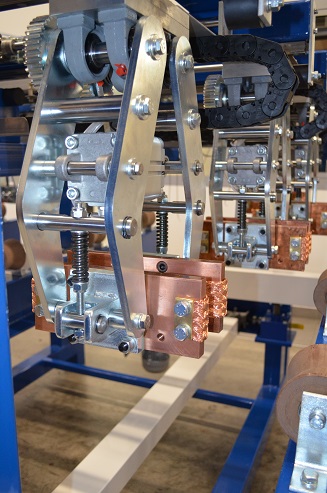

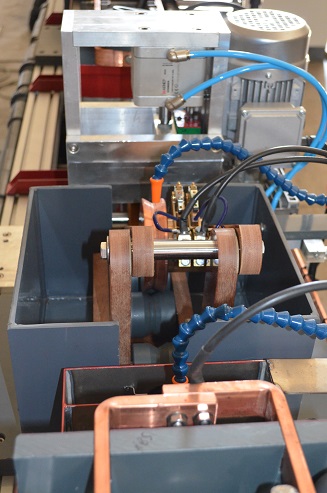

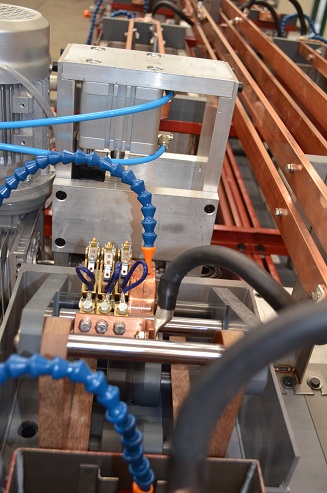

Here are some details of implants that ILMAR has produced